Customized medications aren’t just a niche service-they’re life-saving for thousands of patients who can’t take standard pills. Think of a child who needs a dye-free, sugar-free liquid version of their seizure medicine because they’re allergic to the fillers. Or an elderly patient who can’t swallow tablets and needs a transdermal gel instead. These are real cases. And when these medications are made wrong, the consequences aren’t theoretical-they’re deadly. In 2012, a contaminated steroid injection from a compounding pharmacy caused over 60 deaths. That’s not an outlier. It’s a warning. Preventing compounding errors isn’t optional. It’s the baseline for safe practice.

Understand the Rules: USP <795>, <797>, and <800> Are Your Bible

You can’t prevent errors if you don’t know the standards. The USP <795> guidelines cover non-sterile compounding-things like creams, liquids, capsules. USP <797> is for sterile preparations: injections, IV bags, eye drops. And USP <800> handles hazardous drugs like chemotherapy agents. These aren’t suggestions. They’re enforceable legal standards in most states.For example, USP <797> requires sterile compounding to happen in an ISO Class 5 environment. That means a laminar airflow hood with HEPA-filtered air, cleanroom attire, and no talking or unnecessary movement during preparation. One study showed that skipping even one step-like not changing gloves between steps-increased contamination risk by 40%. USP <795> requires a clean area with ISO Class 8 air quality. That’s not a fancy room. It’s a dedicated space with no food, no clutter, and no distractions.

These standards exist because the margins for error are razor-thin. A 1% mistake in concentration for a pediatric dose can be fatal. A mislabeled vial of fentanyl can kill an adult in minutes. Following USP isn’t about being perfect-it’s about building layers of protection so one mistake doesn’t become a tragedy.

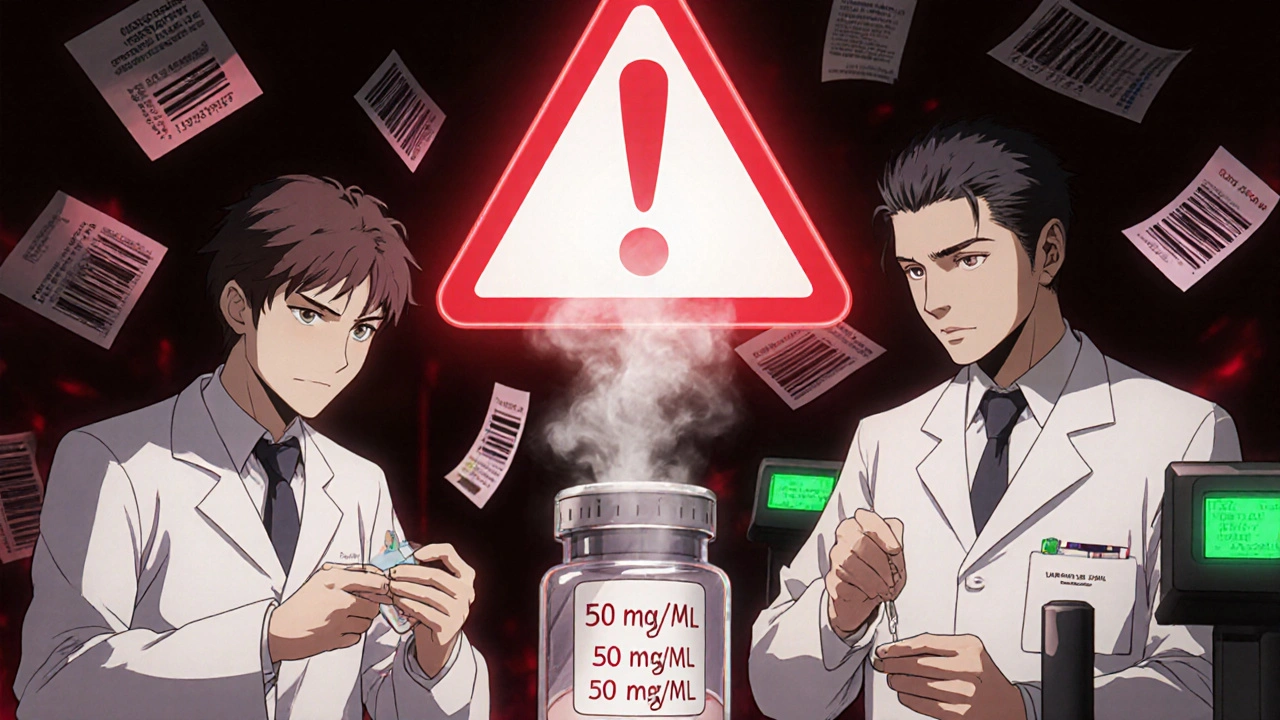

Dual Verification: The One Rule That Saves Lives

No single pharmacist should calculate, measure, and label a compounded dose alone. Ever. The American Society of Health-System Pharmacists (ASHP) says dual verification isn’t optional-it’s mandatory for high-risk preparations. That means two qualified pharmacists independently check every step: the formula, the calculations, the ingredients, the final product.One pharmacist prepares. The second verifies. Not just a quick glance. Full re-calculation. Re-weighing. Re-checking lot numbers. Re-confirming the beyond-use date. A 2022 study in the Journal of the American Pharmacists Association found that this simple step reduced errors by 40%. In one case, a pharmacist misread a prescription for 5 mg/mL of morphine as 50 mg/mL. The second pharmacist caught it because they recalculated the total dose for a 10 mL vial-475 mg instead of 50 mg. That’s 425 mg too much. A lethal dose.

Some pharmacies try to cut corners by having a technician verify. That’s not enough. Only a licensed pharmacist can legally verify a compounded prescription. Training matters. Competency assessments must happen every quarter. Not once a year. Every three months. Because skills fade. Fatigue sets in. And one lapse is all it takes.

Ingredient Verification: Don’t Trust the Label

Active pharmaceutical ingredients (APIs) can be mislabeled, contaminated, or even counterfeit. Relying on the supplier’s label is like trusting a stranger’s GPS. You need to verify it yourself.Use at least two methods. Fourier-transform infrared spectroscopy (FTIR) confirms chemical identity. High-performance liquid chromatography (HPLC) checks purity and concentration. These aren’t luxury tools-they’re basic safety equipment. A 2023 FDA report found that 17% of compounded medications had API concentrations outside the acceptable range. Half of those cases involved ingredients from suppliers not registered with the FDA.

Always check the lot number. Track it. Document it. If a batch is recalled, you need to know exactly which patients got it. Barcode scanning every ingredient upon arrival reduces identification errors by 92%, according to a case study from the University of Tennessee Health Science Center. That’s not a suggestion. It’s a best practice you can’t afford to ignore.

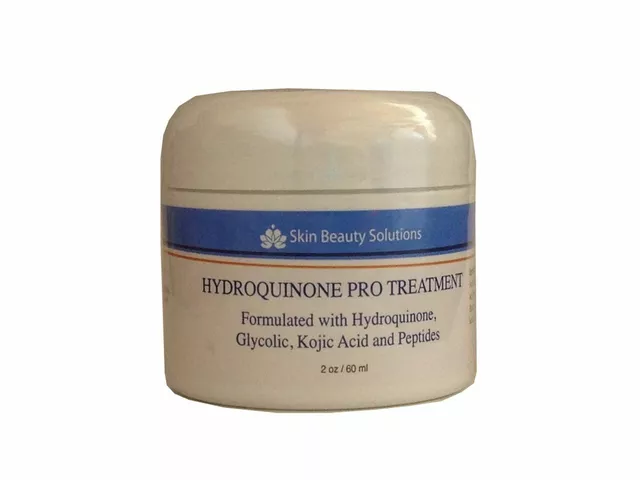

Labeling: The Silent Killer

A mislabeled vial killed a patient in 2021. The label said “Tramadol 100 mg” on the container. But the concentration was 100 mg/mL. The nurse gave 1 mL thinking it was the total dose. It was 100 mg in a single dose. The patient went into serotonin syndrome. ICU. Three days. Survived-but barely.The FDA’s 2023 draft guidance is clear: labeling must use concentration units. Always. “mg/mL.” Not “per container.” Not “per vial.” Not “100 mg.” That’s not just semantics. That’s life or death.

Include the beyond-use date. The storage conditions. The prescriber’s name. The patient’s name. The batch number. If you’re making 10 different versions of the same drug for different patients, each label must be unique. No templates. No shortcuts. Print each one separately. Double-check the patient name against the prescription. Don’t assume. Verify.

Technology: Your Second Pair of Eyes

Manual calculations are the #1 source of error in compounding. A pharmacist doing 20 calculations a day will make a mistake. It’s math. It’s human.Use compounding software. Tools like Compounding.io or PharmScript have built-in checks. They flag impossible doses. They cross-reference drug interactions. They auto-calculate dilutions. A 2022 study showed these systems cut human calculation errors by 40%. Newer AI tools like CompoundingGuard AI are reducing errors by 87% in pilot programs.

But software isn’t magic. It’s a tool. You still need dual verification. You still need to check the output. The system can’t replace judgment. But it can catch the obvious mistakes before they reach the patient.

Training Isn’t a One-Time Event

You wouldn’t let a new driver get behind the wheel without a test. Why would you let a new pharmacist compound without competency checks?Initial training must be 40+ hours. Cover calculations, aseptic technique, equipment use, labeling, emergency procedures. Then, every quarter, test them again. Not a quiz. A live simulation. Give them a prescription. Watch them prepare it. Watch them verify it. Watch them label it. If they make a mistake, stop. Correct. Retrain.

Dr. Henry Cohen, former president of the International Academy of Compounding Pharmacists, says this is the single most effective error prevention strategy. Quarterly assessments aren’t about punishment. They’re about keeping skills sharp. About catching bad habits before they become routine.

Accreditation: The Gold Standard

Not all compounding pharmacies are equal. The Pharmacy Compounding Accreditation Board (PCAB) sets the highest standard. Only 18% of compounding pharmacies in the U.S. are PCAB-accredited as of 2023. But they have 22% fewer errors than non-accredited ones.PCAB requires documented quality control, full traceability, staff training logs, environmental monitoring records, and annual audits. It’s expensive. It takes 12-18 months. It costs $15,000-$25,000. But the cost of one error? A lawsuit. A license suspension. A death. That’s far higher.

If you’re not accredited, ask yourself why. Is it because you can’t afford it? Or because you don’t think it’s worth it? The patients who rely on you can’t afford to take that risk.

When Compounding Is Essential-and When It’s Risky

Compounding isn’t a workaround for lazy prescribing. It’s a tool for patients with real, documented needs:- Allergies to dyes, gluten, or preservatives in commercial drugs

- Children needing precise microdoses (e.g., 0.5 mg of levothyroxine)

- Patients who can’t swallow pills and need liquids, suppositories, or transdermal gels

- Drug shortages where no commercial alternative exists

But avoid compounding for convenience. Don’t compound a drug just because the brand is expensive. Don’t compound a version that’s already FDA-approved and available. Don’t compound without a valid prescription. Don’t compound without verifying the prescriber’s credentials. These aren’t just rules-they’re red flags for preventable harm.

Documentation: Your Legal Shield

Every batch must have a complete record: ingredients, lot numbers, weights, equipment used, environmental conditions (temperature, humidity), verification signatures, and beyond-use date. Retain these for at least one year past the product’s expiration date.If a patient has an adverse reaction, you’ll be asked for this record. If the FDA comes knocking, you’ll need it. If a lawsuit happens, this is your defense. Incomplete records? That’s not negligence. That’s liability.

Use electronic batch records. They’re harder to alter. They prompt you to fill in every field. They auto-log timestamps. They link ingredients to suppliers. They make audits easier. And they reduce paperwork errors by 30%.

Final Thought: Safety Is a Habit, Not a Checklist

Preventing compounding errors isn’t about following a checklist. It’s about building a culture where no one feels pressured to skip a step. Where asking for a second check isn’t seen as weakness-it’s seen as professionalism. Where labeling is treated like a firearm: never assumed, always verified.The patients you serve aren’t statistics. They’re children with allergies. Elderly people who can’t swallow. People with chronic pain who need a different delivery method. They trust you to get it right. And you owe them nothing less than absolute precision.

One mistake doesn’t just affect one person. It shakes trust in the entire system. Don’t let that be your legacy.

What is the most common cause of compounding errors?

The most common cause is calculation errors-especially with pediatric doses, dilutions, or concentration units. A 2023 study found that 42% of serious compounding errors stemmed from incorrect math, often because pharmacists were rushed or didn’t use dual verification. Simple mistakes like misreading decimal points or confusing mg with mcg can lead to fatal overdoses.

Can a pharmacy be fined for compounding errors?

Yes. State boards of pharmacy can suspend or revoke licenses. The FDA can issue warning letters, seize products, or shut down operations. In the 2012 NECC outbreak, the pharmacy’s owners faced federal criminal charges. Even without a death, repeated labeling errors or lack of documentation can lead to fines, mandatory audits, or loss of insurance coverage.

Are compounded medications FDA-approved?

No. Unlike mass-produced drugs, compounded medications are not reviewed or approved by the FDA for safety or efficacy. That’s why the burden of quality control falls entirely on the compounding pharmacy. This is why strict adherence to USP standards and dual verification is non-negotiable-there’s no regulatory safety net.

What’s the difference between 503A and 503B pharmacies?

503A pharmacies are traditional compounding pharmacies that make medications for individual patients based on prescriptions. They follow USP standards but have less oversight. 503B outsourcing facilities operate like manufacturers-they can produce larger batches without individual prescriptions and must comply with FDA Current Good Manufacturing Practices (CGMP). 503B facilities have 22% fewer errors because of stricter inspections and quality controls.

How often should environmental monitoring be done in a compounding lab?

For sterile compounding (USP <797>), environmental monitoring must occur daily-air samples, surface swabs, and particle counts. Media fill tests (simulating actual compounding) must be done twice a year for every technician. For non-sterile compounding (USP <795>), monthly monitoring is required. Records must be kept for at least one year. Skipping this increases contamination risk by up to 70%.

What should I do if I suspect a compounding error?

Immediately quarantine the product. Notify the prescriber and the patient. Report the incident to your pharmacy’s quality assurance team. Document everything-what happened, who was involved, what steps were taken. If the error caused harm, report it to your state board of pharmacy and the FDA’s MedWatch program. Never ignore or cover up a mistake. Transparency saves lives.

Comments (15)